With the development of the 4th generation of armor technologies IBD made a significant step forward towards lighter and cost-efficient protection solutions.

The presentation, given by IBD president Ulf Deisenroth in the plenary session, highlighted amongst others the substantial improvments in protection solutions achieved with the introduction of nano-technologies.

The superior properties of IBD's nano ceramic material with regard to hardness and fracture toughness were tl_files/resources/content-images/products/amap/Comparison of Areal Densities of Modern Ceramics with RHA.jpgdemonstrated in comparison to standard high performance ceramics. As a result the areal density of ceramic armor can be reduced by about 30 %. Alternatively with the same weight a higher protection level can be achieved (see illustration above).

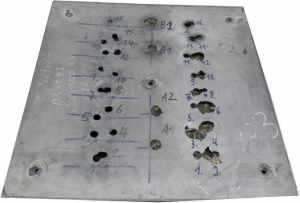

IBD managed to develop - in cooperation with steel manufacturers - high strength nanometric Nitrogen steel with almost the performance of standard ceramic materials. The weight savings compared to conventional armor steel go up to 30%. Furthermore the nanometric steels can be used for structural elements in a vehicle facilitating the integration of the protection as well as structural support. Thus IBD can contribute to advanced vehicle constructions when being involved in the early design phase. This type of steel can also be used as very cost-efficient add-on armor for vehicle upgrades whtl_files/resources/content-images/products/amap/aaaplatte.JPGich was also exemplified in Mr. Deisenroth's presentation.

Another important progress was made with Aluminum-Titanium-Alloys. Their ballistic properties have come close to those of ceramics. Since these alloys are easy to process they do not only help to save weigth, but also allow creating cost-efficient solutions.

First vehicles equipped with IBD's 4th generation type light weight armor kits are already in service.

With the short range, Hardkill Active Defense System AMAP-ADS the survivability concept is completed to form a spherical protection around the platform with a protection level that cannot be achieved with passive components alone. After finalizing the development the system is now close to being fielded.

These new technologies are all together a part of, and integrated in the IBD Evolution Survivability Concept that can be applied to all kinds of platforms (land vehicles, aricrafts, and naval vessels). The main advantages of this concept can be summarized as follows:

- The concept enables protection levels that were not achievable with conventional technologies, especially for light vehicles.

- By balancing the survivability measures within the concept, an optimized protection solution - specifically used in urban environment - can be tailored for any platform (light, medium and heavy).

- The weight savings provide significant tactical advantages in increased payload and maneuverability.

- The modularity of the concept allows easy maintenance and repair by the soldiers in the field as well as upgrades with new technologies at any time.

- Easy maintenance even under field conditions and less wear reduce life cycle costs.

IBD

21.05.2010